Precision Turning with Advanced Lathes for Superior Components

At Tessier Machine Company, our lathes play a crucial role in our ability to deliver precision-engineered components. Lathes are essential for turning operations, enabling us to create cylindrical parts with exceptional accuracy and consistency. Whether you need a single custom piece or a high-volume production run, our advanced lathes are equipped to handle the demands of your project with precision and efficiency.

What Are Lathes?

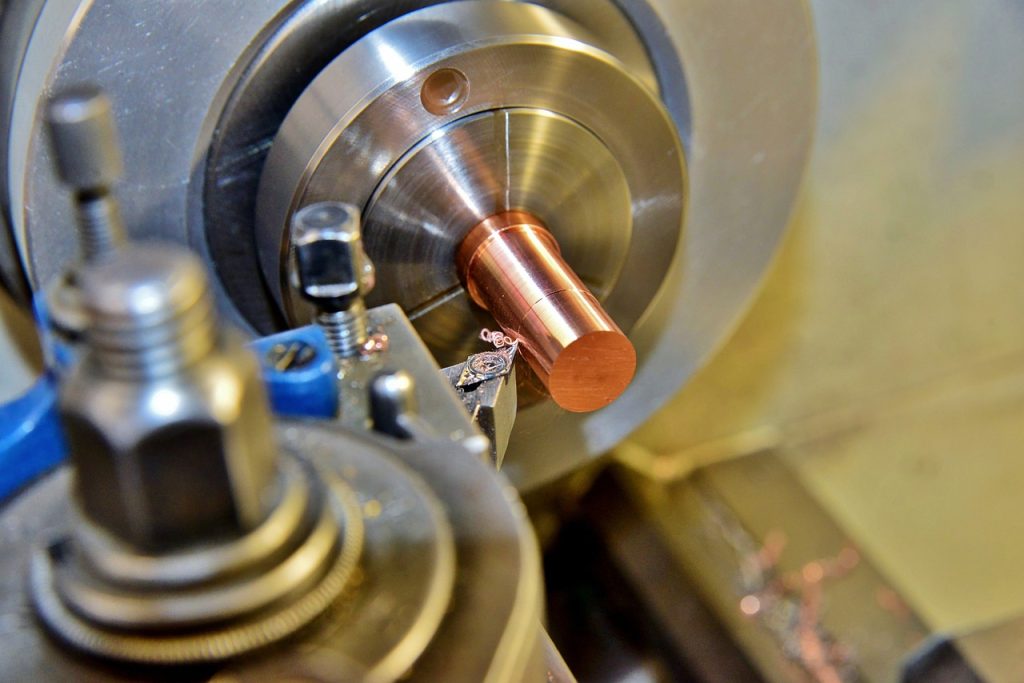

Lathes are versatile machining tools used to shape and cut material, primarily for creating cylindrical parts. By rotating the workpiece against a cutting tool, lathes can produce components with precise diameters, smooth finishes, and intricate details. Our state-of-the-art lathes are designed to handle a wide range of materials and dimensions, making them ideal for various applications across industries.

Our Lathe Capabilities:

1. High-Precision Turning: Our lathes are equipped with the latest technology to deliver high-precision turning operations. Whether working with metals, plastics, or other materials, our lathes can achieve tight tolerances and complex geometries, ensuring that each part meets your exact specifications.

2. Versatility in Material Handling: Our lathes are capable of machining a wide variety of materials, including steel, aluminum, brass, titanium, and high-performance plastics. This versatility allows us to serve diverse industries, including aerospace, automotive, medical, and more.

3. Complex Geometries and Detailed Finishes: With our advanced lathe technology, we can produce components with intricate details and complex shapes that other processes might find challenging. From threading and grooving to contouring and facing, our lathes are equipped to handle the most demanding turning tasks.

4. Efficient Production Runs: Whether you require a prototype or a full production run, our lathes are designed for efficiency and scalability. We can quickly transition from one-off custom pieces to high-volume production, ensuring fast turnaround times without compromising quality.

5. Superior Surface Quality: Achieving the right surface finish is critical for both the functionality and aesthetics of a component. Our lathes are equipped with precision tooling that allows us to produce smooth, high-quality finishes that meet the specific needs of your project.

Why Choose Tessier Machine for Lathe Work?

- Experienced Machinists: Our team of expert machinists has extensive experience in lathe operations, ensuring that every part is crafted with the highest level of precision and care.

- Cutting-Edge Technology: We invest in the latest lathe technology to maintain our competitive edge, allowing us to offer advanced turning solutions that meet the evolving needs of our clients.

- Customization and Flexibility: We understand that every project is unique, and we work closely with our clients to customize our lathe services to their specific requirements, delivering tailored solutions that exceed expectations.

- Commitment to Quality: At Tessier Machine Company, quality is non-negotiable. From the initial setup to final inspection, we ensure that every component meets our rigorous standards for excellence.

Our lathes at Tessier Machine Company are more than just machines; they are the tools that enable us to deliver precision, reliability, and quality in every component we produce. Whether you need simple cylindrical parts or complex turned components, our lathe capabilities are designed to meet the highest industry standards.

Interested in Our Lathe Services?

Contact Tessier Machine Company today to discuss your project and discover how our advanced lathes can deliver the precision and quality you require.